The demand for battery energy storage systems has experienced a sizeable increase across the country and around the world. In light of the growing demand, we decided to add someone to our team to oversee the supply chain for all of our needs relating to energy storage systems paired with our Acumen EMS™. Our Technology and Product Operations Team is essential to ensuring that all components for our products are accurately accounted for and distributed so we can help our customers effectively model and deploy more projects. And in the wake of the COVID-19 pandemic, its aftermath led to numerous supply chain challenges, resulting in global supply chain disruptions for battery and energy storage, hitting an all-time high in the first quarter of 2022.

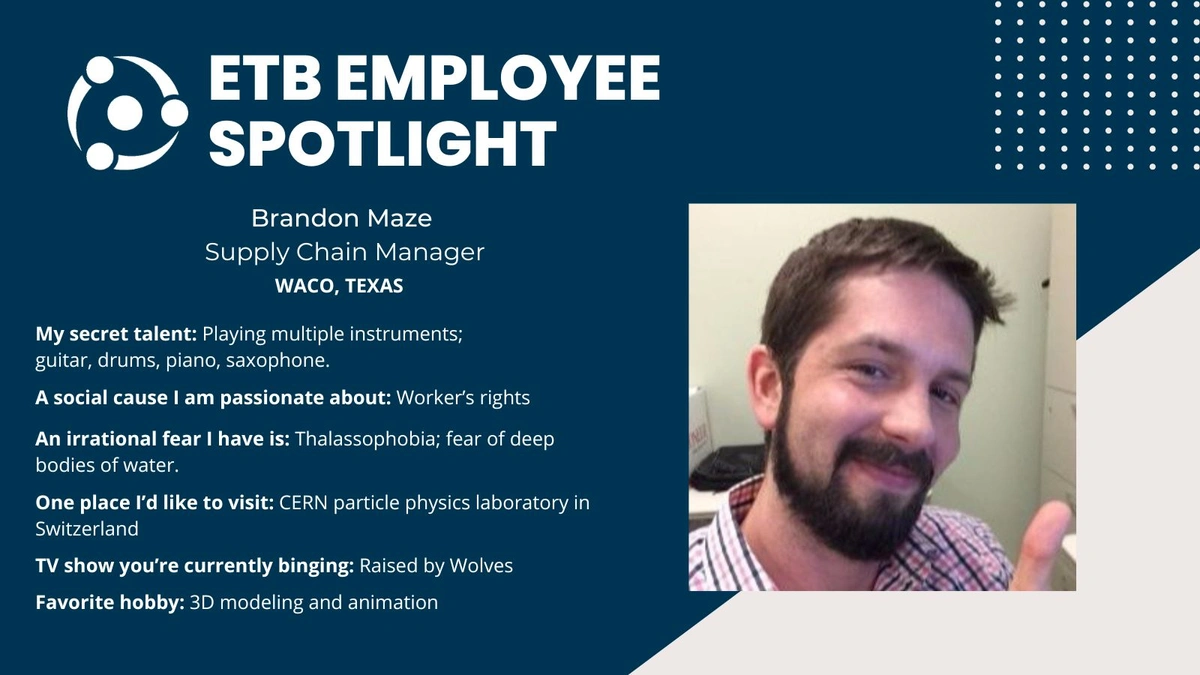

Brandon Maze is ETB’s Supply Chain Manager and based in Waco, Texas. He has been with the team for the last 8 months and comes with an extensive background in procurement and market intelligence. Here, he shares his insights on his experience working on the Technology and Product Operations team, explains how we can learn from the supply chain disruptions stemming from the pandemic, and expressed how his team supports customers in extracting the most value from solar and energy storage projects.

Q: What is your role at Energy Toolbase, specifically within the Operations Team?

A: As the Supply Chain Manager, my role on the Operations Team is to oversee and optimize the end-to-end flow of all the goods and services needed by ETB to run and maintain the business. We focus on ourAcumen EMS, ensuring that all of the pieces to our Acumen Enclosure get to our sites on time and get commissioned. Our team is consistently getting an increasing number of questions related to all things battery energy storage systems, and that’s why we’re continuing to expand our Technology and Product Operations Team.

Q: How have you seen the supply chain change since joining the team at ETB?

A: Since joining Energy Toolbase eight months ago, I’ve seen some issues that were spurred on by the pandemic begin to unwind. This includes labor shortages that were slowing operations, the lacking availability of goods from manufacturing and warehouse closures, and the limited trucking caused by quarantine rules and travel restrictions. I’ve also noticed with our supply chain that the current record-breaking inflation has created a sense of a looming risk on the horizon. Fortunately, there are also some major public and private investments being placed into growing and strengthening the global ESS supply chain and new incentives to bring more energy storage online, including the Inflation Reduction Act that was recently signed into law.

Q: What are some exciting and challenging aspects of working in supply chain management, specifically within solar and energy storage?

A: The most exciting aspect of working in supply chain management is being able to build supply chains that didn’t exist before and being able to work with suppliers to develop new technologies. Our team is constantly looking at different and out-of-the-box ways to adapt to the changing prices and ESS lead times to ensure that it’s a smooth process in getting the necessary equipment to their sites. We want to help them achieve the ultimate goal of deploying more renewables, as quickly and seamlessly as possible.

Perhaps the most challenging part is the task of securing an adequate battery supply due to the EV market. Secondarily, the geographic concentration of raw materials presents some other difficulties. We mitigate these challenges by communicating early and promptly with our customers about any issues or delays we’re seeing, and we’re also in regular communication with our battery energy storage vendor partners to get as much foresight as possible on upcoming changes.

Q: Has your strategy for overseeing the supply chain for ETB changed over time?

A: In a general sense, our focus has remained the same. Our strategy has always been to prioritize the assurance of supply. However, our team, along with battery storage system suppliers, integrators, storage project developers, and potential host customers, have reassessed expectations when it comes to receiving supply, ensuring that shipping times are consistently updated and that the process maintains transparency.

We pride ourselves in having an open line of communication with our customers who have purchased energy storage systems and our Acumen EMS controls. When there is a shipping delay, we reach out immediately to our customers to make them aware and to figure out a solution.

Q: What were you involved in prior to joining the team?

A: Before I joined the ETB team, I worked primarily in procurement and in market intelligence roles that support major capital projects and operations in O&G.

Q: What has been your favorite project to work on in your time at Energy Toolbase?

A: Over the last few months, I’ve been building a tool called the “Site Asset Tracker” to document and analyze all assets associated with each site in the ETB fleet. For this project, it required a deep dive into several sources to gather, cleanse, and validate the data so I can ensure that all purchased items are able to be identified and associated with a particular site. A model has been built to use this information about lifetime costs in conjunction with lifetime performance data to provide a Levelized Cost of Storage (LCOS) in $/kWh. The LCOS metric is widely recognized across the industry and is highly useful for benchmarking the cost of performance of ETB systems both internally against one another and externally against our peers.

Here are some fun facts to help you get to know Brandon a little better: